Custom Drawer Box Construction

Superior Quality & Excellence in Custom Drawers

We have developed systems to quickly and efficiently manufacture high-quality custom dovetail drawers. That is to say, we provide cost-effective products, and we deliver them on time. Our custom size drawers are constructed with:

1. ENVIRONMENTALLY FRIENDLY MATERIALS

2. FLAWLESS DOVETAIL JOINTS

3. CLEAN, TIGHT BOTTOMS

+ ENVIRONMENTALLY FRIENDLY MATERIALS

We manufacture all of our custom drawer boxes with environmentally friendly materials. For example, we use water-soluble PVA adhesives, waterborne finish, and responsibly harvested materials, among other things.

+ FLAWLESS DOVETAIL JOINTS

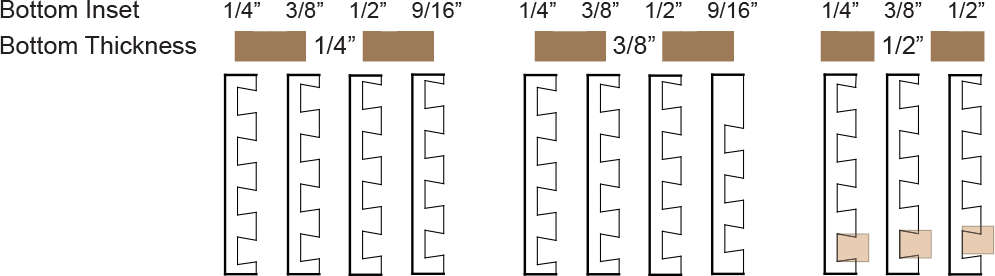

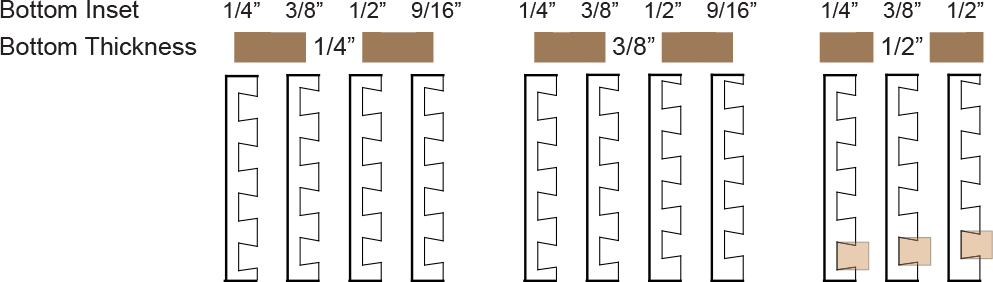

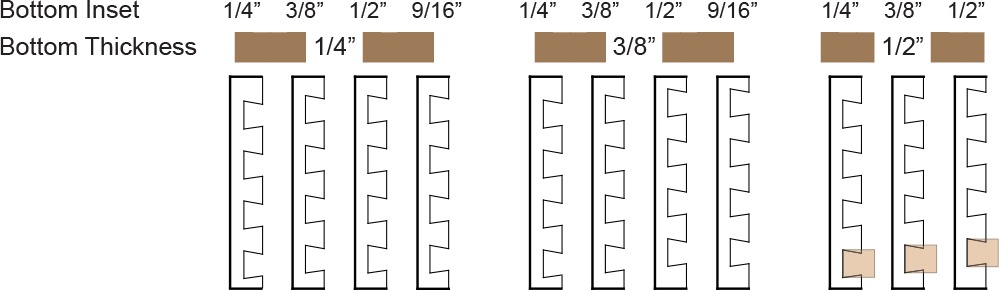

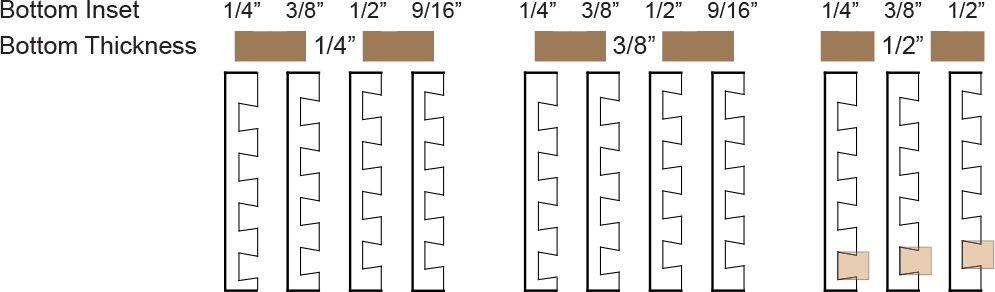

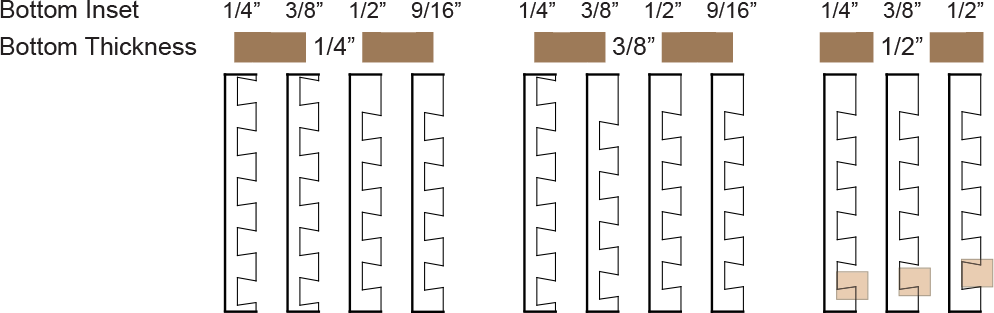

We putty and sand the joints on our solid wood custom dovetail drawers to provide strong, flawless dovetail joints. Moreover, we lay out our dovetails in the best possible way according to the height of the custom drawer box with no half dovetails.

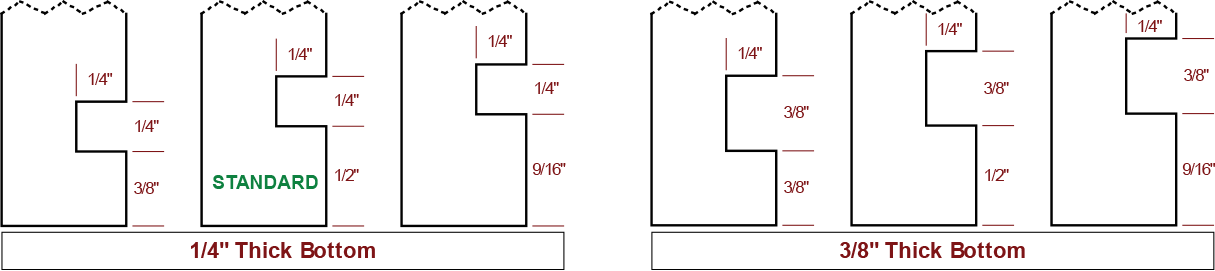

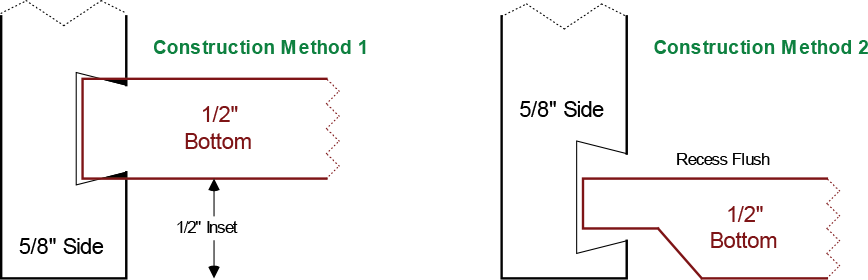

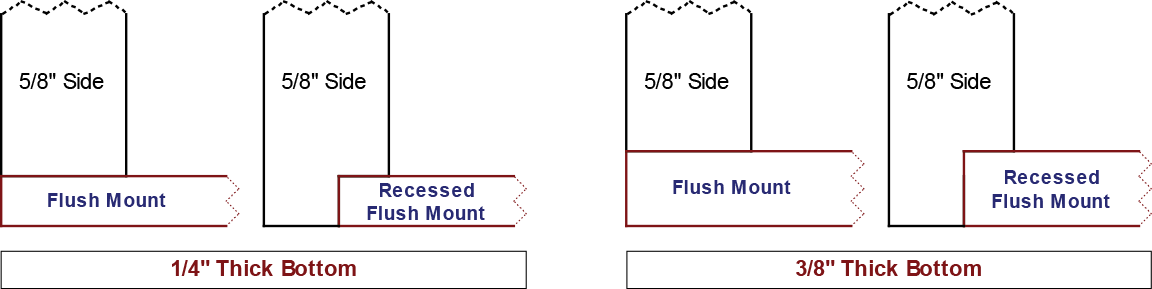

+ CLEAN, TIGHT BOTTOMS

Firstly, we rout the bottoms (hidden on the dovetail joint) into the sides of the custom drawer boxes. Secondly, we staple the bottoms in place from underneath to provide a clean, tight custom drawer box interior.

= SUPERIOR QUALITY

As a result, these features and others combine to provide superior quality custom drawers. View our custom size drawer box construction specifications below, then contact us for a quote on your next job!